Our History of Burner Development

We started to focus on the design and production of burners in 2016.

Our idea is very simple at the beginning-to make a windproof stand for an already sold alcohol stove.

This idea was born because we believe that the effectiveness of the cross stand is low.

We chose a stainless steel alcohol stove and designed our first stand for it. It consists of three pieces of stainless steel. And can be firmly combined with the alcohol stove.

In the same year, we began to try to replace traditional brass burners with aluminum. This will greatly reduce the weight of the burner. What we regret is that the quality of the burners produced by the factory does not fully meet our expectations. While we continued to improve it, we started to make aluminum burners with better performance.

At the end of the year, Capillary Hoop Burner began to be produced and sold. A 0.5mm thick aluminum case has certain strength. The aluminum interlayer with a thickness of 0.1mm can make it bloom quickly. We designed a stand that conforms to the mechanics for it. They are made entirely of titanium alloy and are extremely strong.

They fully meet our expectations, but we want to increase the size of the burner instead of just boiling water for one person. Aluminum is not strong enough to support larger cases, and we knew it was time to look for new materials.

The titanium burner was produced in 2017. It is improved by Capillary Hoop Burner from Toasks. It has a volume of 100ml (60ml is recommended). This size can be used for overnight hikes for 1-4 people. The inner cavity is enlarged, which makes the power of the burner further increased. The structure of titanium and integral stamping gives it unparalleled strength.

For a while, we were obsessed with wasteland style and steampunk. Out of the pursuit of this style, we focus on the design and manufacture of brass alcohol stoves in 2018. We hope to produce an alcohol burner with a distinctive style. Of course, it must have performance beyond the present. We finally decided to use a large number of tubes in the burner and make them replace the existing double-layer combustion chamber. This idea makes us encounter many difficulties. We tried many tubes of different materials and diameters and finally found one that satisfies us.

But the most difficult thing is to obtain a zero-error production method. It is easy for us to make a sample, but it is difficult to ensure that every finished product is as standard as the sample. In the end, we solved this problem, so it has been sold to this day. LOL

The burner continues the foundation of the classic trangia burner. This allows it to be compatible with the Simmering Ring and sealing caps. It can even be put into Trangia's cooking system.

We designed a stand for this new Open Coil Burner one month later. And we still adhere to the original idea. We don't want the stand to block the flame, so it gets a ring-shaped stand. And we have incorporated a strong steampunk style into the stand.

We have further improved the stand. We adjusted some sizes and tenons, which made it compatible with simmering ring. And its load-bearing structure has been further optimized, it can be compatible with 3L pot.

The aluminum Open Coil Burner was produced in 2019. We just did the same thing as we did three years ago—trying to replace brass with lighter aluminum. We selected a heat-treated epoxy-coated aluminum case and aluminum tube. The weight of the burner has been reduced from 68g to 25g.

We choose titanium to make the stand of this burner.

After researching Evernew's DX, we made Turbo Burner System in 2019.

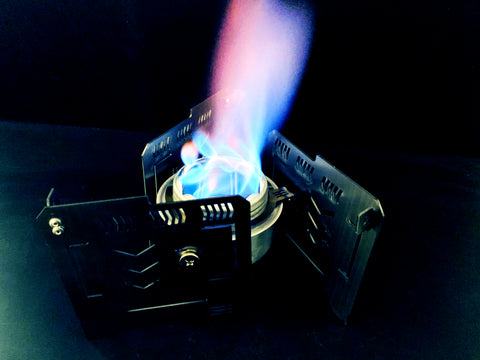

TBS integrates a high-power siphon burner and achieves a balance between oxygen supply and wind protection in a limited space.

After the system is fully activated, a large amount of air will be drawn in from below.

This allows it to boil water quickly and resist a certain degree of climate change.

TBS (EDDY-100) works well. But we hope to get a more powerful burner. So EDDY-200 was manufactured.

It weighs only 100g and has a double-layer structure that allows oxygen to circulate in the interlayer. Our original intention for making it was to serve as a stand for alcohol burners. But it works well as Wood Gasifier Cooker.

We have increased the number of burner pipes in the EDDY-X series. Their flame is more uniform, and had a greater jet velocity.

We absorbed feedback from customers and made a new stand for EDDY-X. The stent is more stable and easy to accept. It is compatible with the Simmering Ring without any hindrance.

We have noticed during many trips that EDDY-200 is still not perfect.

It needs an adjustable bracket to cope with multiple fuels. So we did it.

Thanks to every supporter!

Who doesn't like integration?

We try to make the EDDY-X burner have a stronger stand and adjustable windproof components.

It is Convertible Windproof EDDY-X.

Uh. . Some of our partners think this idea is really cool! So Multi-function Windproof EDDY-X was born. Well, it is the coolest I have ever seen.

But forgive me for taking it out of my backpack.

They have made another "Multi-function"?

Will there be a third brother after this?

The triangular windproof stainless steel alcohol stove has been on sale for 5 years. It is our patriarch. But now is the time to show some new!

EDDY-Z is made of stainless steel. The burner and stand can be separated.